DIE CASTINGS

Die casting are produced

by forcing molten metal under pressure into metal mold casting in

that called dies casting is closely related to permanent mold casting in

that in both processes reusable metal molds are processes differ in

mold filling method. Here as mold filling in permanent

molds casting depends on the force of gravity, die casting involves metal

flow at high velocities induced by the Applicaiton of pressure. Because of

this high velocity we, die casting can produce shapes that are more

complex than shapes that can be produced by permanent mold casting.

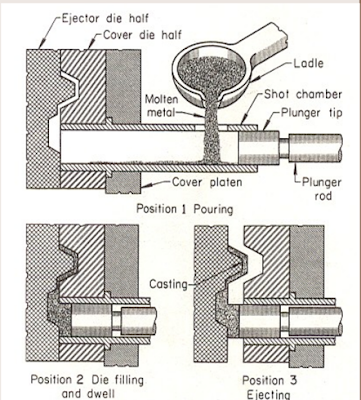

In die casting, after

the die has been closed and locked, molten metal is delivered to a pump/

plunger. The pump plunger is advanced to drive the metal quickly through the

feeding system

While the air in the die escapes through vents. Sufficient metal is introduced to over flow the die cavities, fill overflow wells and develop some flash. As the extraneous metal solidifies, pressure is applied to the remaining metal and is maintained through specified dwell time to allow the casting to solidify. The die opens and the casting is then ejected. While the casting die is open, it is cleaned and lubricated as required. Then the die is closed and locked, and the cycle is repeated.

Advantages of die casting process

• More complex shapes can be made by die casting than by permanent mould casting.

• Because the dies are filled by

pressure, casting with thinner walls, greater length-to-thickness ratio, and

greater dimensional accuracy can be produced by die casting than by most other

casting process

• Production rates are higher in die

casting, especially when multiple –cavity dies are used, than in other casting

processes.

• Because die

casting are produced as almost completely finished parts, the investment in

inventory and factory floor space is reduced to a minimum.

• Dies

for die casting (like moulds for permanent mould casting) can produced many

thousands of castings without significant change die casting dimensions.

• Metal cost is often lower than in

other casting processes, because die casting permits casting of thinner

sections.

• Some

aluminum alloy die castings can develop higher strength than comparable sand

castings.

Limitations of Die Casting Process

Casting

size is limited, casting weight seldom exceeds 20 Kgs. normally is less

than 4 Kgs. Depending on casting countered and gating,

difficulty may be encountered with air entrapped in the die. Entrapped air

is a principal abuse of porosity. The facilities, consisting

of the machine, the auxiliary equipment and dies are relatively expensive.

Because the die castings are small, large quantities of castings are

required for the process to be economical. With few exceptions, commercial

use of the process is limited to metals having melting temperatures no

higher than those of the copper-based Alloys.

Type of Machine

All die casting machine have one of two different metal- pumping system.

-

Hot chamber system

- Cold chamber

system

If the metal being cast melts at low temp. and thus does not attack the injection -pump material the pump can be placed directly in the molten metal bath (hot chamber machine) if the molten metal attacks the pump material at casting temp. the pump must not be placed in the metal bath and a cold chamber machine must be used.

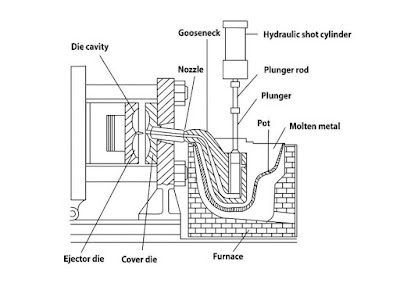

(1). Hot chamber machine

The metal pumping system is which consists essentially of pressure and power cylinders plunger good-neck and nozzle is typical hot system the good-neck containing the presser cylinder and plunger is submerged in the molten metal bath this arrangement allows the metal to be injected in to the die cavities in minimum time and with minimum decrease in the temp. hot chamber die casting machine are used mainly for casting machine are used mainly for casting of melting metal such as zinc-tin and lead alloys.

(2). Cold chamber system

In a cold- chamber machine, the shot chamber is unheard except for the heat from molten metal ladle into fore casting and plunger tip is water cooled to pouring of the short chamber mounted horizontal with a pouring hole in the top of the chamber wall.

|

| Cold_chamber_Machines |

Advantage of cold-chamber machine

The main

advantages with col-chamber machine are the relative freedom from attack of

molten metal an equipment because the short chamber and plunger are not

submerged in the molten metal meal and high injection pressure range from 8000

to 90,000 psi pressure to 50,000 psi, have been in special or experimental

application.

The main disadvantages with cold- chamber machines are.

- The need for an auxiliary method of feeding metal

- Longer cycle time than is needed for hot-chamber operation.

- The possibility of metal defects due to loss of superheat.

- There is chance of Porosity due to entrapped air in Shot Sleeve while carrying molten material from furnace.

The volume of metal needed for the shot determines shot-chamber

and plunger tip sizes. If the shot chamber is too large, the metal will lie in

the bottom of the chamber and the chances of air entrapment are increased. If

the shot chamber is too small, there will be insufficient metal for the casting

or metal will splash out of the pouring hole. When the machine is being set up,

the plunger tip should be adjusted so that it will immediately start covering

the plunger hole as the plunger advances. In most operations, the actuating

system is such that the plunger is advanced slowly until the pouring hole is

covered and the plunger then moves rapidly to inject metal into the die.

Optimum plunger speed varies with the alloy being cast, the size and shape of

the casting and the design of the gate and runner. Plunger speed range from 150

to 900 ft. per min.

Operation cycle of a vertical cold-chamber Die Casting Machine with sprue bushing.

A vertical cold chamber die casting machine with vertical parting die is shown in Fig. The injection system includes a vertical shot chamber connected directly to the corner die half by sprue bushing. A hydrolytically actuated lower plunger covers the bushing hole in the vertical cold chamber. While metal is being ladled into the chamber from above (position 1). After the metal has been ladled, the upper or shot, plunger is actuated. As the pressure builds up, the lower plunger retracts so that metal is force through the sprue bushing into the.

Operation cycle of a vertical cold-chamber Die Casting Machine with sprue bushing

After a

dwell cycle for metal solidification, the upper plunger is withdrawn, while the

lower plunger is rises & shears of the remaining slug of metal

One disadvantage of this type of machine is that, in having two operating plungers, one of which doubles as a trimmer, it requires frequent maintenance work

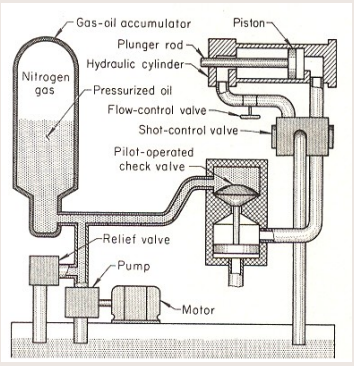

Injection Pressure Systems

The pressure used in injection (shot) systems is generated either in air cylinders or in hydraulic cylinders. A hydraulic pressure system usually includes a positive vane- type pump and a gas-oil accumulator as shown in fig.4. The gas-oil accumulator is a pressure vessel that supplies the required volume of oil at the high pressure and rates necessary to fill the mould cavity rapidly with molten metal. An accumulator permits the use of a smaller pump: when an accumulator is used, the volume capacity of pump need only be sufficient to recharge the accumulator between casting cycles.

|

| Injection_Pressure_Systems |

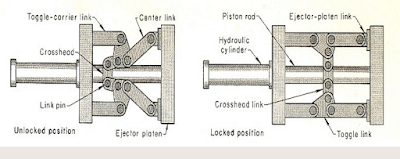

Die Locking Mechanism

The most common locking system is shown in this figure. In

comprising a hydraulic-cylinder stroke and dual toggle action, this system

combines the stroke and power transmitted by a hydraulic cylinder with the

mechanical advantage of the link system. The locking action begins when the two

faces of the die come in contact and compression at the dir faces is fist

established. When the three outer link pins are aligned and the crosshead-link

position is normal to the alignment of the pins, maximum force on the die

equals tensile forces in the tie rods.

|

| Die_Locking_Mechanism |

Ejection Systems

Die casting dies usually include an integral Systems for ejecting the casting by machine action. When the die is closed, ejector pins contacts the casting and safety (return) pins contacts the parting-line face of the casting fixed half of the die. Both sets of pins are secured in a movable ejector plate assembly. After the die opens, the casting is ejected by the forward movement of the ejector-pin plate. The force required to activate the ejection system may be furnished by mechanical knockout plate, a rack and pinion or a hydraulic cylinder.

| |

| Ejection_Systems |

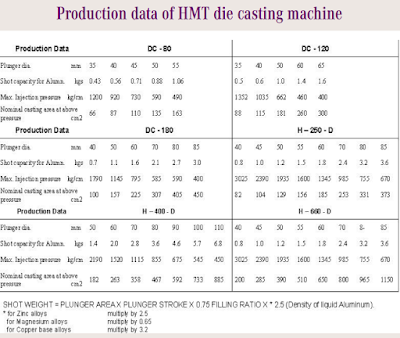

Machine

selection for making any casting should be based principally on clamping force

and operating stroke, length of shot stroke, mailshot pressure, maxi. die

opening and die size, max. & min. die height, clearance between beams,

over-all size and cost.

The

rule of thumb for selection of die casting machine size is to use the smallest

machine that will do the job. This will ensure fundamental economy of operation, since the larger the machine, the slower its cycle. For example

400-ton machine can cycle about twice as fustian 800-ton machine. Clamping force

is not necessary the deciding factor n the selection of die a casting machine.

Die dimensions must be considered. The machine adequate tonnage for casting a

part may have insufficient platen area or tie-rod spacing for the die or the

opening stroke may not be sufficient for removal of casting

Another

factor is the cost of the equipment, which must be amortized in the

cost of operation. The cost of auxiliary equipment for die casting machine is

usually proportionate with the size of the machine.

|

| Specification_of_HMT_die casting_machines |

|

| Production_data_of_HMT_die_casting_machine |

For more information, please comment here. ConversionConversion EmoticonEmoticon